Brass Ball Valves (Couple-Collector) according to the Iranian National standard No. 16222 and is

made of hot forged brass. The main form of ribs is calculated in inches based on EN ISO-228

Standards.are usually used in building facilities, floor heating systems, warm and cold building

water supply networks. The valve is quarter-turn and opens and closes with a 90-degree rotation

of the handle. Internal and external surfaces are coated with nickel to avoid long-term corrosion

against minerals of water or other environmental corrosives. The ball inside the valves is covered

with chromium in addition to nickel to minimize its erosion due to friction with plastic tape.

The sealing angle of this type of valve is +15 degrees, the best sealing angle for ball valves.

A total of 100 % pressure tests are performed on all valves during a pre-defined period, and torque

tests and impact tests are performed randomly too.

Technical Specifications

| Order No. | Size (inch) | A (inch) | B (mm) | D (mm) | H (mm) | L (mm) | Operating Temperature (C) | Working Pressure (bar) |

|---|---|---|---|---|---|---|---|---|

| 5100 | G1/2*16 | 9 | 16 | 8 | 30 | 61 | 5 - 80 | 16 |

| 5101 | G1/2*20 | 9 | 20 | 11 | 32 | 61 | 5 - 80 | 16 |

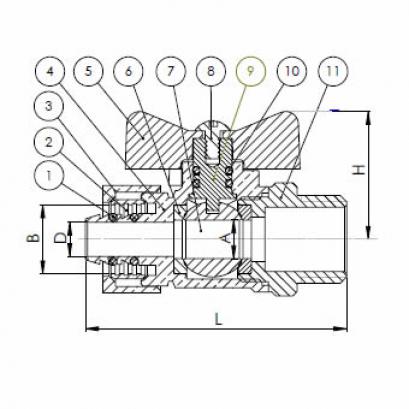

Analysis of Materials

Body and all parts of ball valves manufactured by this Company are according to the last standards, the analysis of which is according to the following table

| No. | Name of pieces | material |

|---|---|---|

| 1 | O-Ring | Silicon |

| 2 | Ring | MS58 brass (nickel plating) |

| 3 | Nut | MS58 brass (nickel plating) |

| 4 | body | MS58 hot forged brass (nickel plating) |

| 5 | Handle | Aluminum with electrostatic paint coating |

| 6 | Ball seats | PTFE |

| 7 | Ball | MS58 brass (Chromium-Nickel plating) |

| 8 | Screw | Electroplated iron |

| 9 | Stem | MS58 brass |

| 10 | O-Ring | NBR rubber |

| 11 | Bonnet | MS58 brass (Nickel plating) |