Y Strainer is designed and produced of hot forged brass according to national and international

standards and applies to building pipelines, engine rooms, irrigation, and agriculture systems,

various types of water heaters and packages, and processes that deal with water, oil, or even gasoline.

Advantages

Mounting a uniform strainer of the SS (Stainless Steel) for all of the valve sizes will extend lifetime of the screen after its mantling and dismantling for cleaning.

Furthermore, the screens of the strainers upper than size 1 ¼ " consist of the uniform two-layer screen that will increase several times as much the strainer resistance for its extra surface and preventing characteristics against resistance loss.

Technical Specifications

| Order No. | Size (inch) | A (inch) | D (mm) | L (mm) | H (mm) | H1 (mm) | SW (mm) | Operating Temperature (C) | Working Pressure (bar) |

|---|---|---|---|---|---|---|---|---|---|

| 5150 | G1/2 | 1/2" | 15 | 58 | 41 | 55 | 26 | 150 | 16 |

| 5151 | G3/4 | 3/4" | 20 | 70 | 45 | 62 | 32 | 150 | 16 |

| 5152 | G1 | 1" | 25 | 85 | 57 | 78 | 39 | 150 | 16 |

| 5153 | G1 1/4 | 1 1/4" | 32 | 90 | 67 | 93 | 49 | 150 | 16 |

| 5154 | G1 1/2 | 1 1/2" | 41 | 99 | 75 | 103 | 55 | 150 | 16 |

| 5155 | G2 | 2" | 50 | 123 | 91 | 127 | 68 | 150 | 16 |

| 5156 | G2 1/2 | 2 1/2" | 60 | 148 | 108 | 151 | 85 | 150 | 16 |

| 5157 | G3 | 3" | 65 | 158 | 120 | 169 | 98 | 150 | 16 |

Analysis of Materials

Body and all parts of Y strainers manufactured by this Company are according to the last standards, the analysis of which is according to the following table

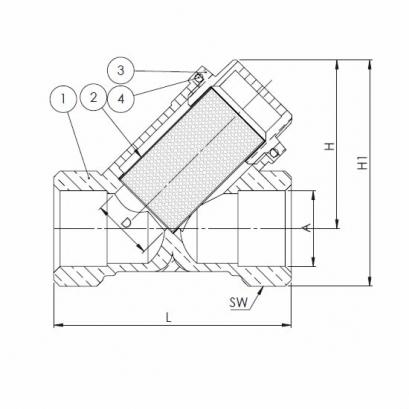

| No. | Name of pieces | material |

|---|---|---|

| 1 | body | MS58 Hot Forged brass (2 1/2" & 3" Casting) |

| 2 | Grid | Stainless steel |

| 3 | Cap | MS58 Hot Forged brass |

| 4 | Sealing O-Ring | NBR rubber |